Do you need assistance?

Fill in the form, leave your number and we will contact you.

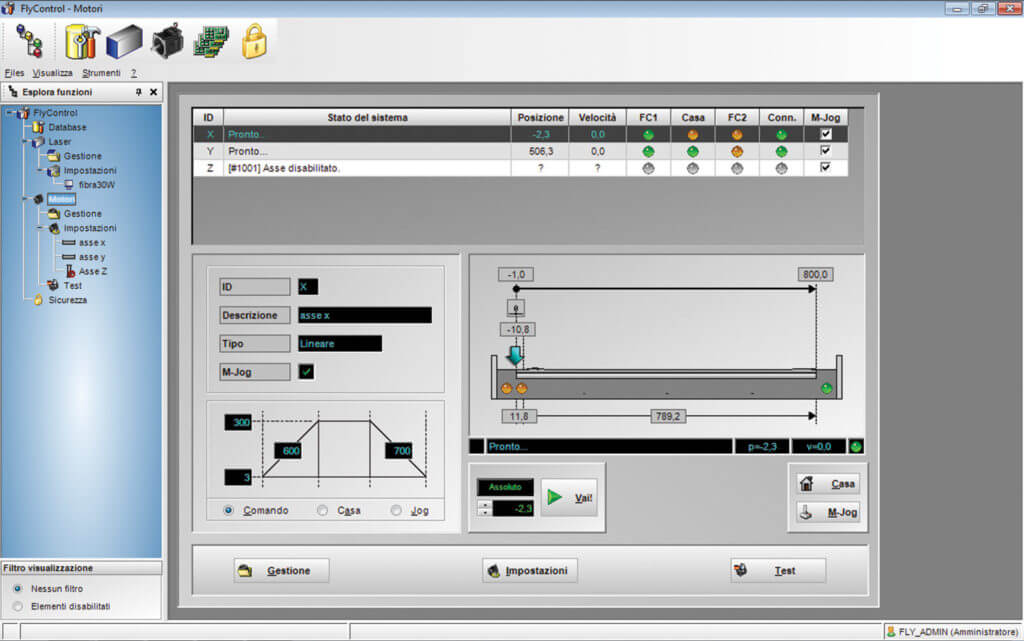

We connect to your PC and with our FlyControl diagnostic software we analyze and solve the problem

LASIT Sistemi e Tecnologie Elettrottiche S.p.A.

Via Solferino 4

80058 – Torre Annunziata (NA)

P.Iva 02747991210

C.F 01803670643

Copyright © 2024