We decided to provide our followers and customers from the foundry sector with a unique laser engraving experience.

In May, we will open the doors of our Laboratory to make you see how we laser engrave cast components.

This three-day event will be like a virtual one-to-one meeting between you and one of our sales agents and specialized laser technician. This way, you can solve your doubts and learn more about this world.

Plus, you can ask any question about laser engraving cast components or how to obtain permanent engravings. You’ll discover how not to jeopardize laser engraving results after invasive processes, such as sandblasting and shot peening.

Stay in touch to be always up-to-date with LASIT.

We’ll email you the instructions on how to book your virtual visit to the laser engraving workshop. Moreover, you’ll have the possibility to read foundry-related content every week before the event.

If you work in the foundry industry, you cannot miss any of the things that will happen before the event in May.

The first event for registered people is dedicated to laser engraving for traceability purposes and 2D codes.

Check out our Youtube Channel! We have prepared a series of videos about laser engraving die-cast components. Search for the 1-minute Laser videos on YouTube. Every week, we post a video about cast components.

These 1-minute videos summarize important information and present the event that will take place in May. Mario Palmieri, our laser application expert, will address the following topics:

If you register, you’ll receive the above material before the event, even if you can’t attend.

You can decide whether to participate or enjoy the content you received via email upon registration. The content will always be available, so you can read it any time you want.

What are you waiting for? The first video on Traceability and 2D codes is already online!

Subscribe using this form if you want to receive information and content beforehand

By submitting this form you accept ours privacy

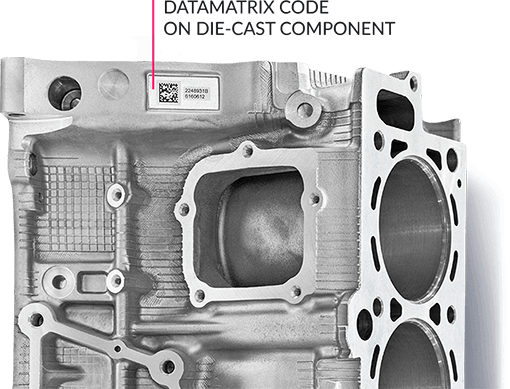

A few years ago, laser marking unfinished components when they were just out of the die was impossible because of the loss of quality caused by the subsequent treatments.

This happened mostly on DataMatrix codes. Today, thanks to high-performance lasers and optimal technical parameters, we can ensure complete traceability by marking components immediately after they come out from the die. This way, DataMatrix codes are always legible even after invasive processes, such as sandblasting and shot peening.

We at Lasit have developed different standalone and automated solutions through in-line laser integration.

These solutions include: 24 systems – developed over the last ten years – that allow for loading and unloading during machining; 5 special stations to be integrated into automated islands, whose strength is the productivity resulting from the cooperation of robots.

Cast components undergo different processes, such as sandblasting and shot peening, which are necessary yet invasive, as they risk making the DataMatrix code illegible.

We at Lasit have developed a strategy to prevent the DataMatrix code from becoming illegible after various processes. We managed to do this thanks to deep engravings and specific parameters and shapes for die-cast components. 100W, 200W or 300W lasers are those we used the most as they also ensure extreme speed.

Did you like this article?

Share it on

LASIT Sistemi e Tecnologie Elettrottiche S.p.A.

Via Solferino 4

80058 – Torre Annunziata (NA)

P.Iva 02747991210

C.F 01803670643

Copyright © 2024