LASIT is a company that develops laser marking and engraving technologies and does so with passion and dedication.

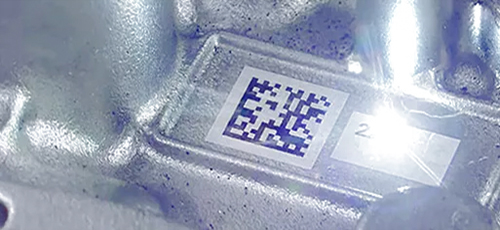

We are big enough to make a difference, but small enough to take care of every single customer. Our Study and Design team ensures traceability, production chain control, brand visibility and industrial process automation.

Our qualified salesmen and technicians are always available to respond to the needs of our customers to guarantee the very best service.

Our offerings include customized solutions for the Automotive, Medical, Home appliance, Electronics, Hydraulics industries and also for the Military. These solutions are developed by a team of mechanical, electrical and software engineers.

Over the past 30 years, we have developed Traceability and Aesthetic laser marking systems for metal applications, including tools, die-castings, and medical components. We are experts in marking plastics, such as electronic components, gadgets, and household appliances.

Every new customer becomes a new partner. We share goals and transform product requirements into functional paths for their implementation. Increased productivity and production process optimization are just a few examples of the requirements we have met over tim

Values

Our tiny 65 m2 first office was home to our desire to develop optomechanical systems (scanning heads for directing beams) for the LASER industry.

Today, we build “turnkey” systems that integrate the laser, robots, rotary tables, optical instruments for quality control, and more.

Our mission is to build a Technology HUB that can be a meeting ground for the brilliant minds of our country, too often spoiled and abandoned.

We want to create a globally recognized hub that allows us to demonstrate that developing these types of solutions is possible, that talented people in our country do not need to leave to find a satisfying, challenging job in terms of technology and innovation.

1990 - A brilliant idea

Lasit was founded in a village on the Sorrento peninsula in 1990. Marco Ievoli and Candida Colonna came up with the idea, developing a new technology for that time: laser marking for cylindrical components.

In 1991, LASIT launched the 3-axis laser marking head, immediately after the American Company, General Scanning. In 1993, LASIT designed and manufactured its first lamp laser for Hoffmann S.r.l. followed shortly afterwards by Beretta.

1995 - The production challenge

In 1995, LASIT won its first important challenge for ISCAR. We realized an insert-marking system that will open up to a long-lasting collaboration.

LASIT designed and manufactured an air-cooled Nd:Yag laser, an innovative technology for the early ‘2000s.

This was the year of industrial fiber laser, and LASIT stopped producing in-house. We started designing industrial and customized automation systems, becoming a long-standing partner of ISCAR, BSH and BERETTA.

2007 - Continuous research

People in LASIT have always focused on research and know-how. We cooperate with research institutions including the ILT institute based in Aachen. With them, we created a real time laser beam control system.

2013 - The family grows bigger

In 2013 Marco and Candida’s children – Giò and Ginevra – joined the company. They gave the sales and management department a boost, increasing production and the number of partners. The company moved from the Sorrento peninsula to a larger plant in the industrial area of Torre Annunziata.

One year later, Rosario Sessa, Marco Ievoli, Pietro Apicella and Carmine Nardone designed the first laser system that worked with an anthropomorphic robot.

2015 - Internationalization

The company has become a benchmark for European and international companies. Lasit opened new headquarters in Milan and Augusta, USA, with LASIT USA. It created its WebTV, a new technology to reduce distance with its partners. Now, you can watch what is happening at the Lasit plant in real-time.

Lasit is always working to create a positive atmosphere and boost ambition. Today, people work in a 12.000 sq.m plant . It includes a relaxation area, a gym, a library, and an arcade to promote team-building and make employees’ breaks more fun.

LASIT began its expansion and internationalization process in 2015, opening a dedicated Service office in Milan, Italy and a dedicated Sales office in Augusta, in the United States.

In 2019, we expanded our horizons and opened our boarders eastward, opening a business office St. Petersburg, Russia.

Following our customers and analyzing the market, we took another step in 2021, opening a business office in Tychy, Poland. It was difficult and required a good deal of commitment, especially due to the virtual communication forced by the pandemic. Thanks to a fantastic team and the market’s positive response to our products, we achieved significant results, beyond our expectations.

Our office in Spain comes from the requirement to expand westward, covering a market similar to the one in Italy and which definitely requires personalized support. LASIT Laser Iberica represents LASIT’s will to penetrate the peninsula, starting with our existing customers and expanding to give more customers the benefit of our experience.

LASIT Laser Mexico is our office in Mexico City dedicated to service and sales support for its large customers, especially in the automotive industry.

Our Bologna commercial/service office allows us to serve the companies in Northern Italy with sales and support as we provide off-the-shelf parts and a sales engineer on staff.

One of our experts is ready to answer your questions and advise you on the best solution for your traceability or visibility needs of your brand. We take care of the project from careful analysis to implementation, without intermediaries, from start to finish.

LASIT Sistemi e Tecnologie Elettrottiche S.p.A.

Via Solferino 4

80058 – Torre Annunziata (NA)

P.Iva 02747991210

C.F 01803670643

Copyright © 2024