Powerclean

Powerclean is a high-power fibre optic system specifically for ultra-fast cleaning operations.

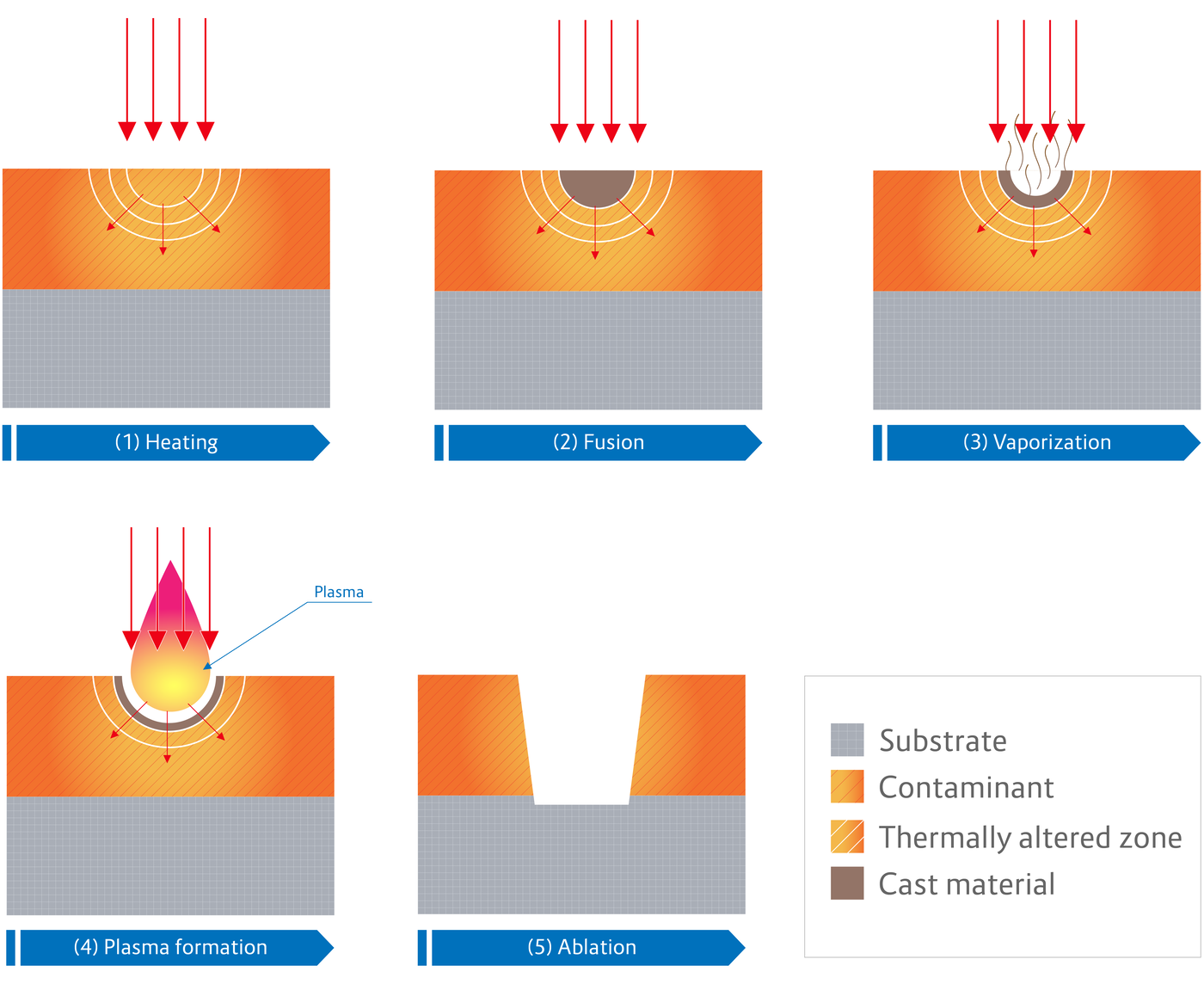

Removal of the contaminant takes place thanks to the energy input of the laser, which performs an ablative process.

In particular, the process consists of the following steps.

For the process to take place, it is crucial that the laser’s energy input is sufficient to overcome the specific ablation threshold of the contaminant.

Powerclean guarantees precise and ultra-fast results and can be used with different accessories and in different modes as needed.

This cleaning laser can be used to prepare surfaces for welding, to remove oxides, paint and rust, to clean moulds and to remove metal coatings.

Powerclean is particularly suitable for integration on a robotic arm.

This is because the laser source is separate from the control rack unit and the fibre and cables meet the requirements for resistance to the stresses imposed by robot handling. For this reason, the strength and durability of the system is ensured.

One of the main advantages of the Powerclean-robot relationship is that the laser program is integrated into the robot program, i.e. there is direct communication between the two components.

Both will work by only programming one.

There is no need to have two computers or two management systems. This is an advantage in terms of saving time and money.

Modalities of use

In this mode, the laser operates without a PC control system, making it suitable for integration into production lines where space is normally limited. In this case, an operator interface is not required and installation time is considerably reduced. Whether this is possible depends on the process required and must be discussed in detail.

In the standard configuration, the laser is operated from a PC via our FlyCAD software. In a highly automated environment, the FlyPowermark software can be used as an alternative to FlyCAD, which offers a simplified operator interface.

If the application requires it, the interface can be customised to handle different ways of data entry, e.g. accessing the client’s factory system (database, web services, TCP/IP protocols, etc.).

Furthermore, since the system can potentially handle an infinite number of lasers, it is possible to design the application to simultaneously control all lasers on the line.

We find the best laser solution only for you.

Fill out the form to receive a free consultation, one of our experts will answer all your questions.

By submitting this form you accept ours Privacy Policy.