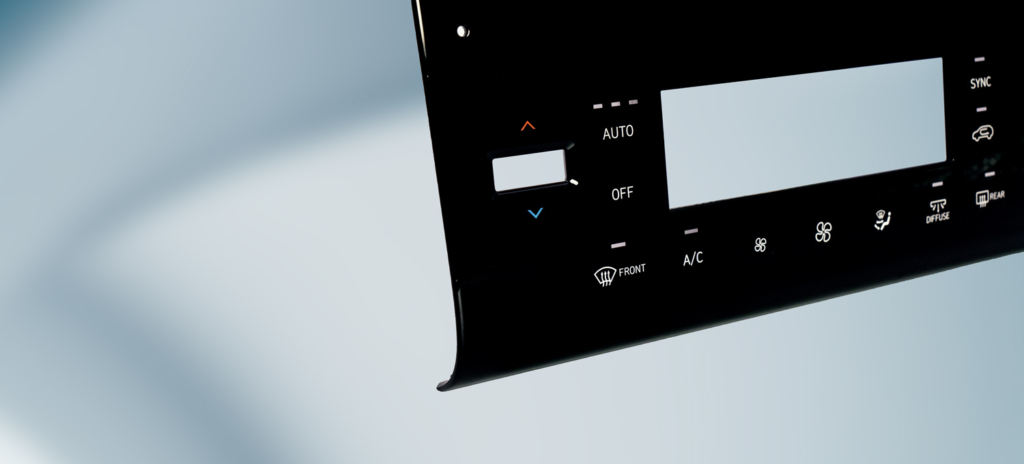

Laser marking on different plastics

Laser marking processes on plastics

Carbonization

Carbonization makes it possible to create strong contrasts on shiny surfaces. During this process, the laser heats the surface of the material (to a minimum of 100° C), causing the emission of oxygen, hydrogen, or both. The result is a dark area with a high concentration of carbon.

During carbonization, the laser works with a lower than average energy. This results in a longer marking time than other processes. Carbonization can be applied to polymers or biopolymers such as organic materials such as wood, leather and hide. Mainly used for darkening, its contrast is not maximal on components that are already dark .

Colour change

Laser marking involving a color change process is basically an electrical process, which rearranges the macromolecules (by changing the direction). In this case, the material “dilates” by partially expanding. It is not removed or eliminated. The “pigment” elements in the base material always contain metal ions. Laser radiation changes the crystalline structure of the ions and the level of hydration in the crystals. Consequently, the composition of the element itself undergoes a chemical transformation, causing a color change due to the greater intensity of the pigment.

Unlike the previous processes , the laser frequency is at maximum. Each pulse has a reduced energy. This is to avoid excessive expansion of the material or the removal of part of the surface.

All plastic polymers can undergo this color change process . In most of the cases, the color change is towards a darker color; a light effect is rarely obtained.

Removal

Expansion

Laser marker for plastic: advantages

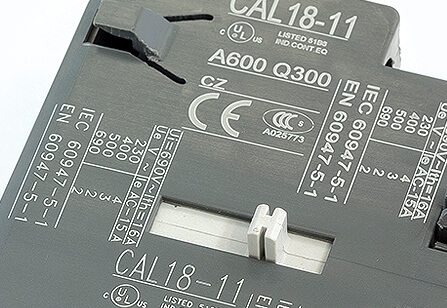

Resistance

Savings

- Direct marking on plastic does not involve any cost for consumables, such as inks, chemicals, pastes or sprays

- Direct marking avoids all costs for the disposal of chemicals

- No preventive or subsequent treatment necessary for laser processing

- Lower risk of wear and tear (and therefore necessary replacement) of mechanical parts

Ecology

Precision

Speed

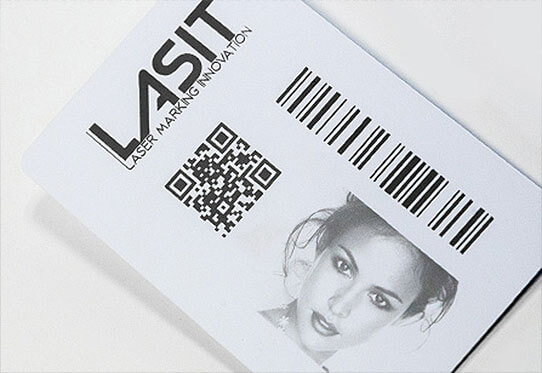

- It is possible to create markings in a very short time, even with variable content (e.g. serial numbers, codes)

- A wide range of different marking can be done without retooling or changing tools on the machine

Versatility

- It makes it possible to trace characters with minimum-sized fonts and geometric designs while maintaining clear readability

- It is possible to do photoengraving in a short time

Integration with factory systems

Lasers marking on plastic

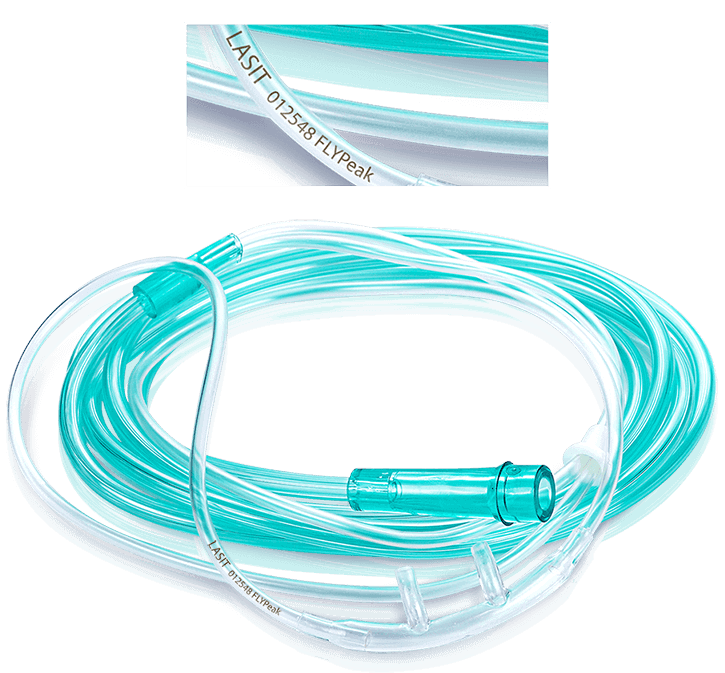

The most common lasers for plastics applications are the famous UV laser, the FlyPeak green wave laser by LASIT and the traditional Green light laser with fiber optic source. In most cases, the use of a MOPA laser or variable pulse laser is recommended: thanks to pulse duration control, this laser ensures maximum performance on more difficult applications.

Laser technicians carry out tests to see which laser is best for achieving the desired result on specific plastics. Usually, the parameters initially used are those listed below. Based on the results of the first tests, it is possible to identify those best suited to the specific processing desired.

Test parameters

ABS White

PA66 GF 30 Black

POM C Black