The Powermark FlyPico laser has a fiber source laser well known for its precision in black and imperceptible picosecond laser marking. It’s the first choice when it comes to post-marking treatments, like citric or nitric passivation cycles. This type of laser is being used more and more for marking Medical Devices, Home Appliances, and Jewelry.

Powermark FlyPico for integration is a robust, durable product that works in any industrial environment. It can be used for laser marking:2D codes, alphanumerical codes, one-dimensional codes, and logos.

Powermark FlyPico can perform the most complex processing of a traditional infrared, specifically for imperceptible marking that required faster execution. The smaller spot concentrates the energy in a single point, resulting in better quality and no reflections. This feature is very useful for medical device manufacturers.

As with all LASIT laser markers, this one can be integrated into the line with Profibus, Profinet, or Ethernet/IP protocols.

All our Laser Markers are qualified for Industry 4.0. LASIT supplies all the necessary technical materials and instructions for connecting the laser to the factory’s system at no additional cost. LASIT can ship this product in 48 hours.

At this time, laser marking on medical devices is the most sought-after technology for UDI codes. Its safety level and permanence have the highest standard compared to any other alternative. Without a doubt, laser marking greatly reduces the risk of mistakes and produces tiny DataMatrix codes (0.5 x 0.5 mm) that are perfectly readable on extremely small devices.

Laser marking on metal and medical plastic follows all the essential traceability parameters, including:

In this mode, the laser operates without a command PC, and it can be integrated into production lines with limited space.

It does not require an operator interface, and installation is much faster.

As an alternative to FlyCAD, the FlyPowermark software with a fully customizable operator interface is available for automated environments. It can manage several data input modes, for example, access to the company factory system (database, web services, TCP/IP). It can potentially manage an infinite number of lasers, making it possible to design applications to command all the lasers on the line simultaneously.

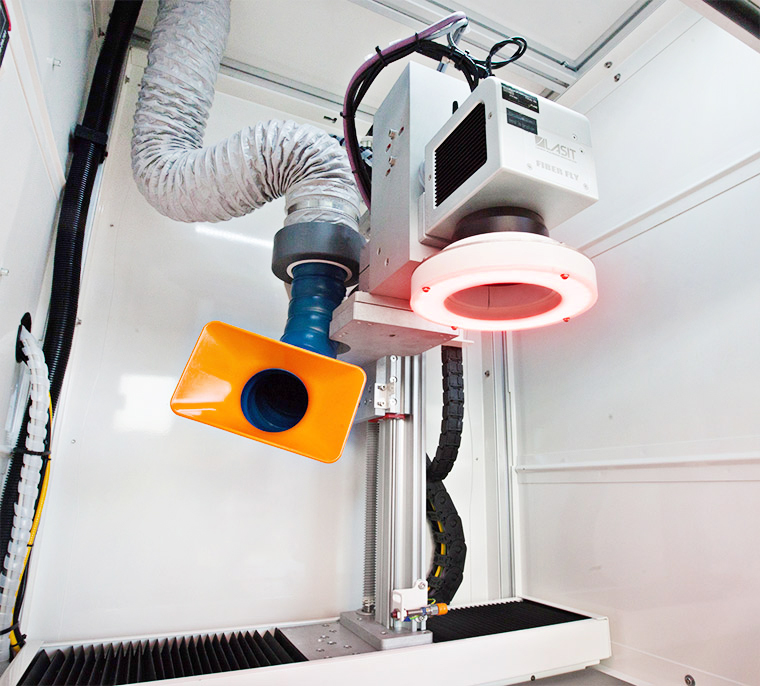

In addition to the lateral vision system, LASIT equips its laser markers with the TTL vision system. This vision system is directly integrated into the laser scanning head and is perfect for validating (reading and grading) DataMatrix codes without moving the laser or the camera.

This is possible because the light reflected by the part is directed on the camera’s detector in the same exact path as the laser beam.

The integrated circular light offers a clear view inside the framed area, and the brightness can be adjusted.

There are two possible scenarios for DMC validation:

The system is equipped with the 3-axis head for laser marking large, cylindrical, or irregular surfaces, which allows a constant focal elevation to be maintained.

Mechanically, it consists of a linear motor system, two X and Y rotary devices (allowing the laser band to be moved along the axis), and a third axis for focusing. The laser band passes through a scope equipped with a mobile lens that, in turn, is assembled on a linear traverse.

The software automatically adjusts the operation. This system allows the focal point of the laser to advance without it moving along the Z axis. Powermark FlyPico can also be equipped with an Autofocus system, which allows the focal distance to be corrected automatically. It consists of a laser sensor integrated optimally in the LASIT software.

Wavelength

1030nm

Source

Ytterbium fiber

Pulse duration

2 ps

Marking area

It depends on the focal point

Input/output

Standard I/O – Custom interface

Cooling method

Water cooled with chiller

Housing weight

17.5 kg

Laser and scanner weight

5.5 kg

Communications protocol

Profinet, Profibus, Ethernet, RS232

Available power

50 or 100 W

| Focal | Marking distance (mm) | Marking area (mm) |

|---|---|---|

| EFL 100 | 150 ± 10 | 87 (61x61) |

| EFL 160 | 225 ± 10 | 140 (100x100) |

| EFL 254 | 325 ± 10 | 220 (150x150 |

| EFL 330 | 395 ± 10 | 290 (205x205) |

| EFL 420 | 500 ± 10 | 424 (300x300) |

LASIT Sistemi e Tecnologie Elettrottiche S.p.A.

Via Solferino 4

80058 – Torre Annunziata (NA)

P.Iva 02747991210

C.F 01803670643

Copyright © 2024