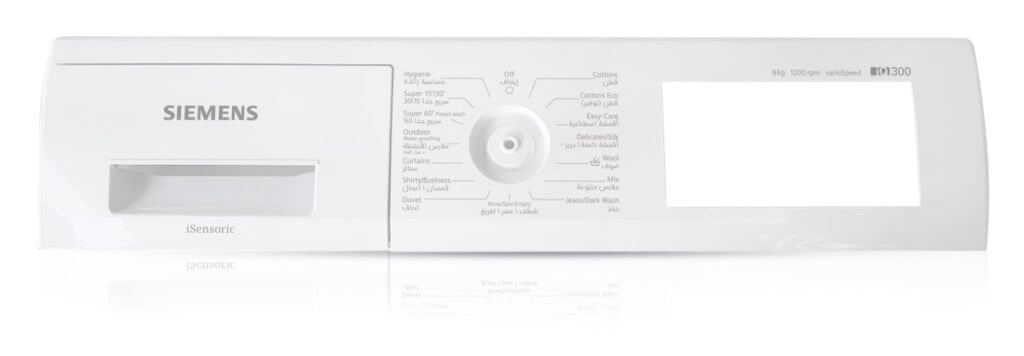

Since 2017, LASIT has been involved in a Research and Development project for the laser marking of Home appliance industry components, which puts companies such as BSH, Whirpool, Electrolux, Arçelik and Daewoo Electronics in first place worldwide.

Laser marking is the only technology that guarantees the permanence of its result and, the more this becomes evident, the more the big players consider lasers as the best method for marking codes, logos, texts and numbers on their components.

The precision of the laser plays an essential role: the small size of the spot, in fact, allows for even more complex, microscopic and elaborate markings, at a level of perfection not achievable with other systems.

The Home Appliance industry is characterized by a wide variety of products, which in turn are composed of irregularly shaped parts with complex and large-sized geometries, making it difficult to build versatile systems and develop the technologies needed to mark them.

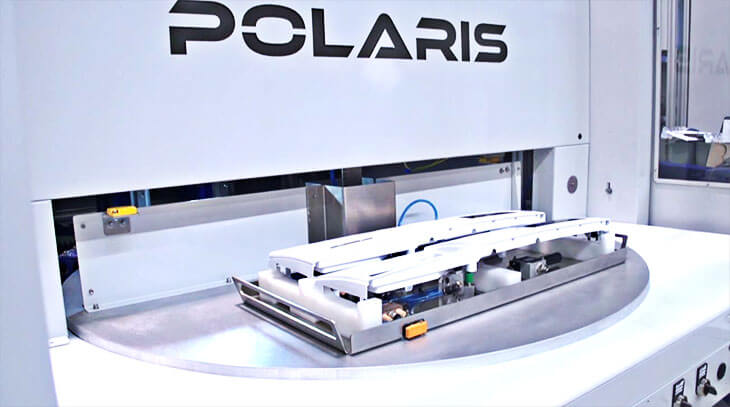

LASIT thus began its POLARIS project, first carefully studying the industry needs and then proceeding with the development and implementation of a line of laser markers able to address the three main problems:

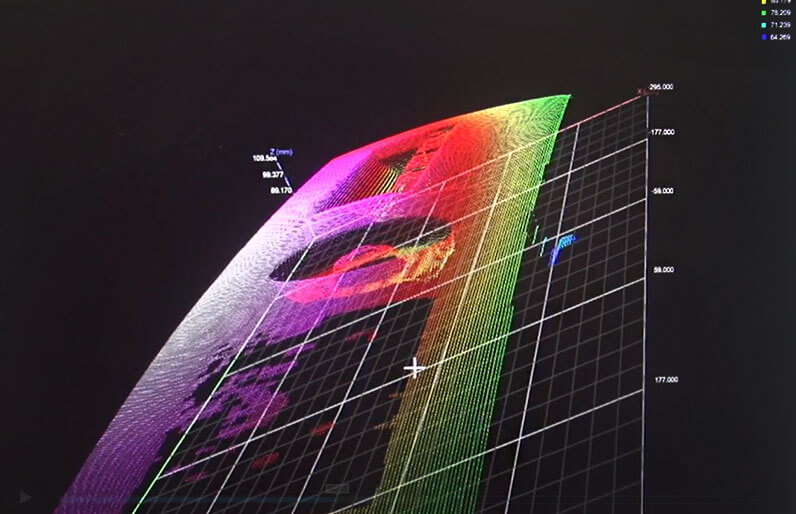

The problem component surface irregularity has been solved by using:

Marking quality was another major challenge in the implementation of the POLARIS project. In fact, even though we were sure that the best laser for ABS and PMMA was a 355nm laser, a great deal of testing had to be performed to get to the point of choosing the UV and finding the ideal parameters.

To make this laser system as productive as possible, we have equipped it with:

Let’s take, for example, the alternative to lasers currently most used in the household appliance industry; namely, pad printing. This technique involves the use of a soft, flexible pad (generally made of silicone), through which an indelible ink film is transferred from an engraved steel or photopolymer plate (pad printing cliché) to the surface of the substrate.

Did you like this article?

Share it on

LASIT Sistemi e Tecnologie Elettrottiche S.p.A.

Via Solferino 4

80058 – Torre Annunziata (NA)

P.Iva 02747991210

C.F 01803670643

Copyright © 2024