Why do we use laser marking?

Traceability

Laser marking technology is primarily used to ensure the traceability of industrial components due to its versatility, high speed, and wear resistance compared to other technologies.

Integration

The easy integration into existing industrial lines is also a plus, as well as the possibility for laser markers to collaborate with robots and be equipped with vision systems for reading and verifying marked codes.

Aesthetic

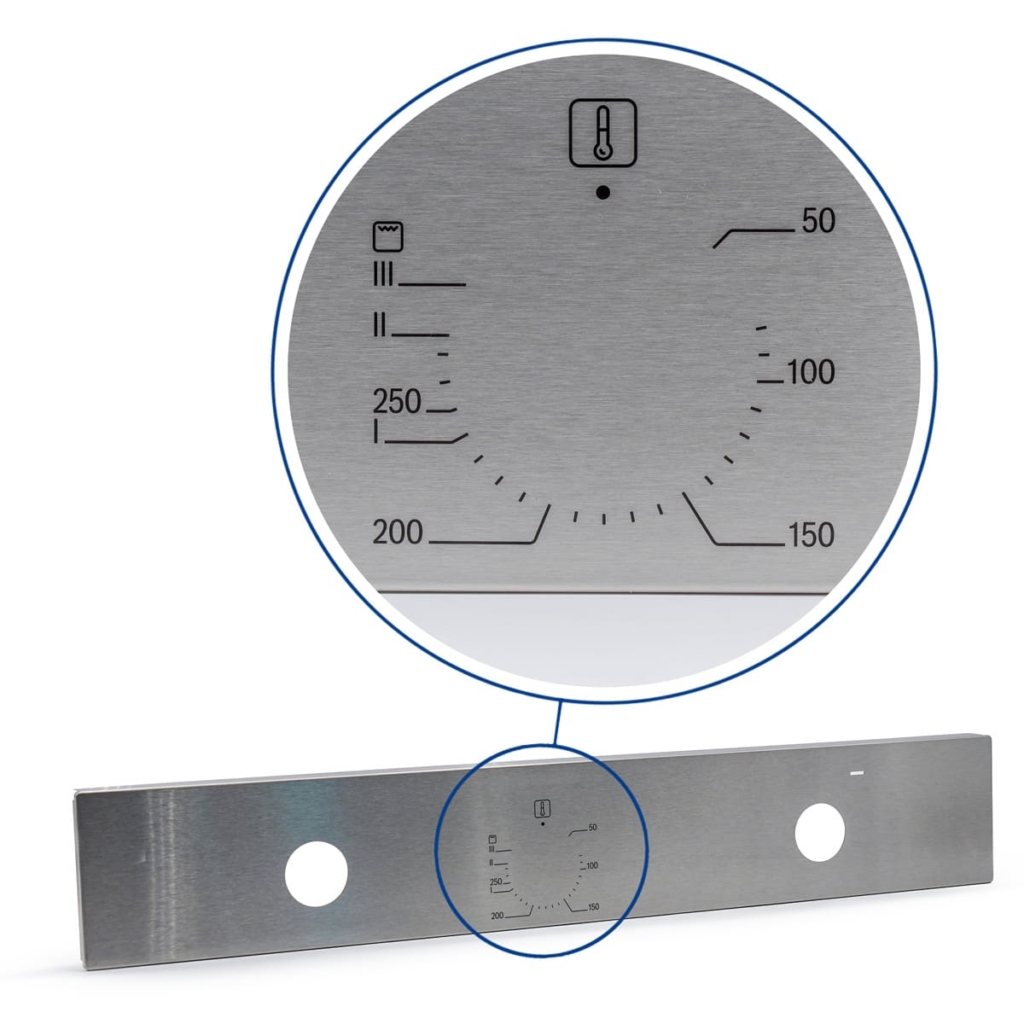

Lasers can be used to mark or engrave complex geometries and logos with unparalleled precision. The wide range of wavelengths and powers ensures that virtually any material can be marked with high-contrast and permanent graphics.

Functional marking

Laser marking technology is also used to modify the physical properties of the material’s surface, achieving the desired result with unmatched repeatability.

Advantages of Laser Marking

Precision

Laser marking allows for high-resolution designs with thin lines and the ability to mark small or delicate components with precision.

Durability

Laser markings are resistant to wear, aggressive chemical agents, and environmental factors, ensuring long-term readability and traceability.

Speed

Laser marking is a fast and efficient process that contributes to increased productivity for businesses.

Versatility

Laser marking can be applied to a wide range of materials, including metals, plastics, ceramics, and glass, marking virtually anything.

Non-contact

Being a contactless process, laser marking eliminates the risk of damaging sensitive components and ensures a clean process and precise results.

Environmental sustainability

The absence of consumables such as inks or abrasive tools allows for a more cost-effective and environmentally friendly daily use compared to other technologies with inks or polluting agents to dispose of.

Conclusion

Laser marking technology has become indispensable in modern industrial processes, offering a combination of precision, durability, and efficiency. Its applications continue to expand across different sectors, providing a reliable solution for permanent and high-quality markings on various materials. The careful consideration of laser parameters and features ensures that laser marking systems meet the specific requirements of each application, contributing to the advancement and improvement of industrial processes worldwide.