A laser marker with a traditional template is not enough for the automatic laser marking of 1600 tags.

Since productivity is one of the most important requirements of tag producers, we have developed a system that allows easy management of laser engraving, so as to reduce the operator’s work to automate the processes.

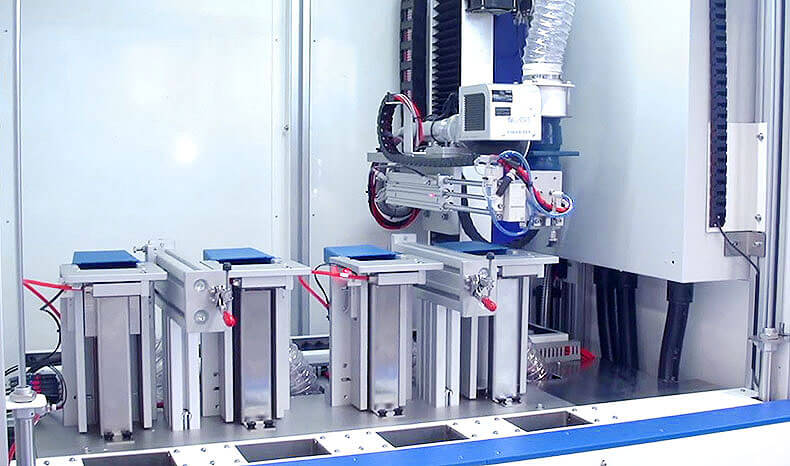

The Flylabel laser marker is configurable up to 4 loaders: from a single one, which can contain up to 400 tags with the Pick&place system that regulates disorderly unloading, up to 4 different loaders that can manage both disorderly unloading and ordered loading with the same Pick&place system.

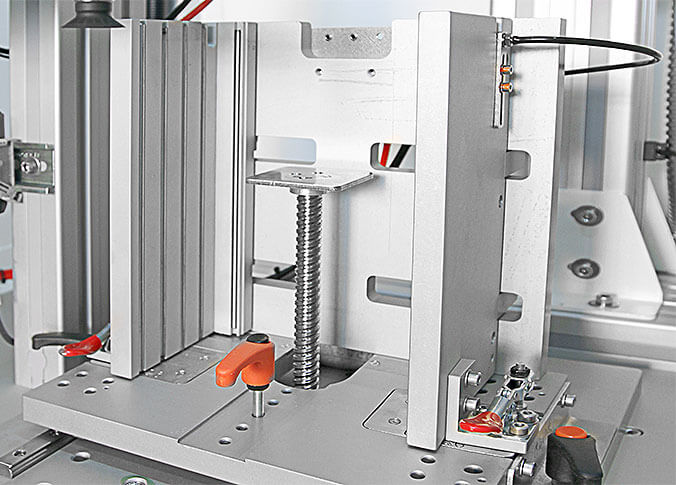

The XZ axis system with 800×300 mm stroke then manages the position of the laser head for laser marking of each row of components with extreme precision.

The operator loads the tags in the loader and the laser marking program for tags, capable of handling one or more operating sequences, is started. LASIT usually creates software according to customer needs, guaranteeing its ease of use. The main advantage of FlyCAD is its ability to progressively manage data, automatically populating the contents of the laser engraving on the tags according to the production order.

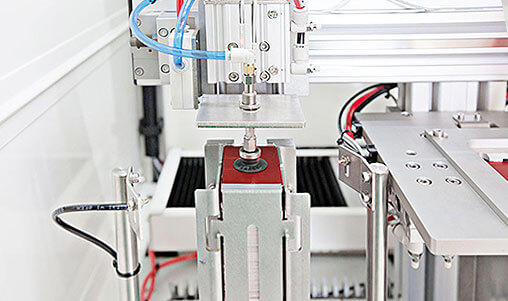

Once loading has been completed and the software started, the operator’s work is finished. The tags are automatically marked and then picked up by a Pick&Place system (equipped with a suction cup) and unloaded.

It is possible to install different size loaders in the same housing if different size tags need to be marked. This gives the laser marker great versatility and a strong productive advantage.

Did you like this article?

Share it on

LASIT Sistemi e Tecnologie Elettrottiche S.p.A.

Via Solferino 4

80058 – Torre Annunziata (NA)

P.Iva 02747991210

C.F 01803670643

Copyright © 2024