Laser marking is the tool manufacturers use to permanently mark their products for two reasons: traceability, guaranteeing a controlled supply chain, and appearance by decorating the product with their logo, function symbols, and graphics. You encounter many marked products every day. Such as:

- Transportation: all vehicle products have a DataMatrix ID code, usually 2D

- Household Appliances: all household appliances (the up-market ones) are laser marked: washing machines, microwave ovens, ovens, stove tops, etcetera

- Faucets: the logos on faucets, both writing or designs, are made using a laser marker

- Kitchen tools: glasses, forks, knives, pots, and even some types of plates are decorated with the manufacturer’s logo made using a laser marker

- Medicine and orthodontics: medical tools – for the patient’s safety – are identified with a code that is usually made using a Picosecond laser

- Fashion accessories: belts, buckles, earrings, rings, and more, are all laser marked so that the symbol is indelible and will last forever, like a diamond

- Packaging and boxes

How does laser marking work?

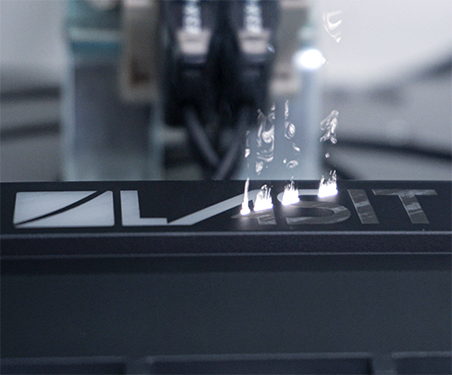

Laser marking uses a laser beam to emboss permanent markings on the materials. It can mark any metal, plastic, or organic material.

With a suitably powerful light beam, the product is heated, changing the appearance of the surface in specific locations, allowing information for traceability or designs to be reproduced on the surface.

As this is a “no-contact” technology, laser marking allows not only deep engraving and product identification, but also extremely clean, detailed processing which can ensure a high-resolution finish without ruining the materials’ surface with burrs or abrasions.

Laser marking is also designed to resist acids, corrosion, and weathering. Another advantage is the speed of this technology. Laser marking machines can quickly and accurately engrave any material or surface, increasing the company’s productivity while guaranteeing maximum safety for the equipment users.

What are the benefits of laser marking?

1. Precise marking with constant quality

One of the main advantages of laser marking over other technologies is its precision. This article explains the advantages of laser marking compared to dot-peening.

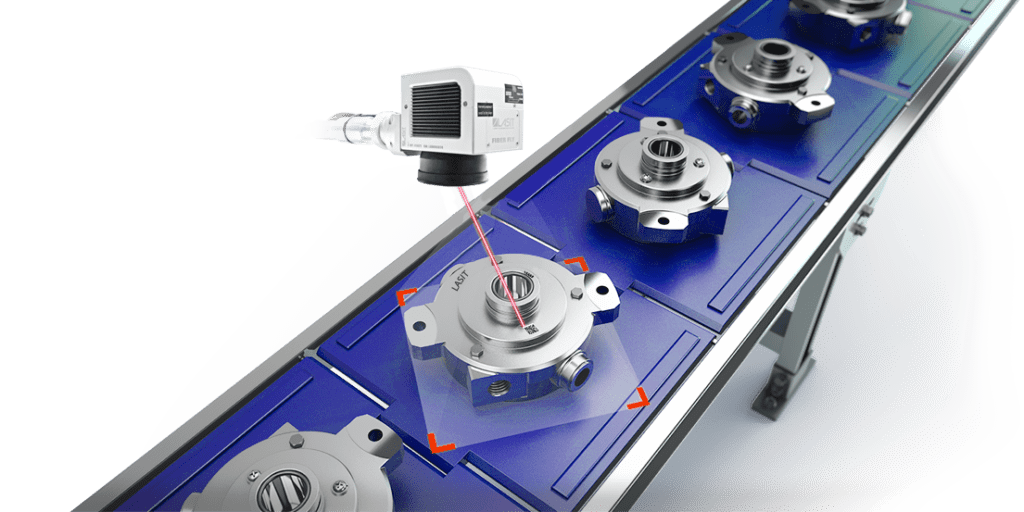

Even the smallest or most complex graphics are no problem for laser markers as the laser spot is tiny. Even a 0.5 mm DataMatrix code is marked with absolute precision and is always legible on both metals and plastics.

2. Speed

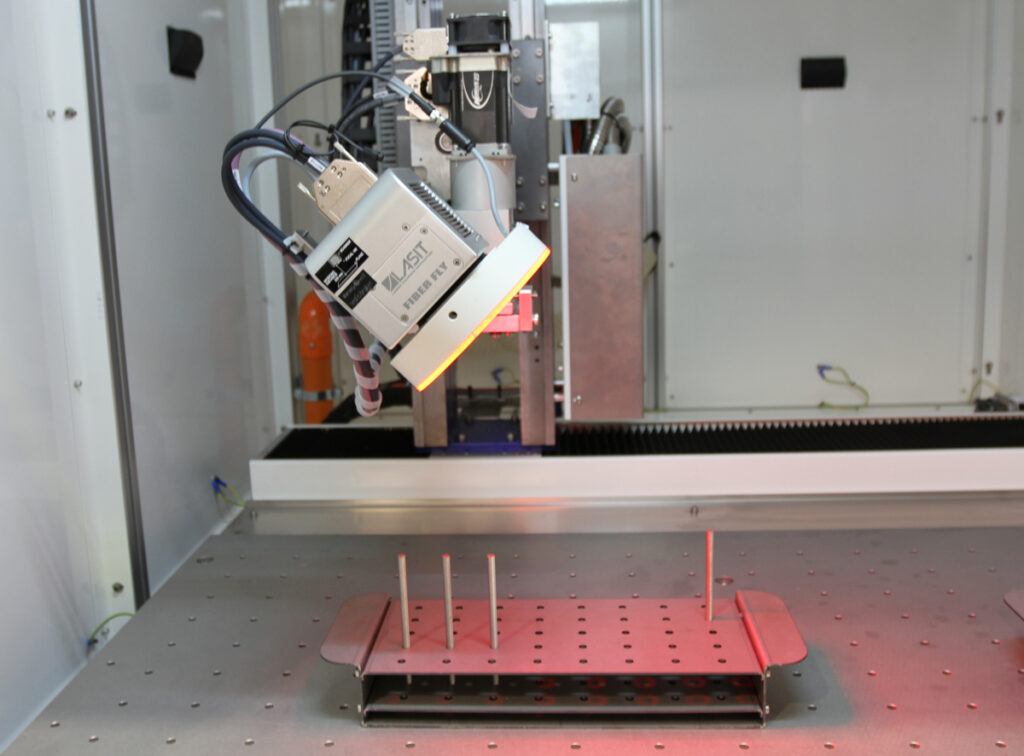

Laser marking is one of the fastest processes on the market. High productivity and economic advantages result from cycle time reduction and automation in those industrial processes where laser marking can be implemented. LASIT is specialized in supplying turn-key systems, which allow manufacturers to integrate complete in-line solutions. These solutions are not limited to laser marking. They can check the code, position the part, mark multiple parts at the same time, and perform tests and complex procedures, thanks to our FlyCAD and FlyControl software.

3. Durability

Laser marking is permanent and resistant to wear, heat and acids. Based on the laser parameter regulations, markings that do not deteriorate the part’s surface can be made. For more information on this topic, please see the article on laser marking metals and laser marking plastics.

The video below illustrates how we performed a salt spray test to demonstrate the resistance of a 2D code, even on a worn part.