Why laser marking?

Metal is the material that is most often laser-marked. The entire automotive supply chain consists mainly of metal products. Many hydraulic and medical components are also metallic. The demand that laser marking most often satisfies is that of traceability. This requires the marking of identification codes, most often QRcodes and DataMatrix. LASIT laser markers with the proprietary FlyCAD software are able to create codes with extreme versatility. The software is easy to use and allows automatic data management, connecting directly to the customer’s MES-ERP system. LASIT laser markers can also integrate a vision system for verification and grading of marked codes.

Within one station of the production chain, the traceability of its products is ensured by a high level of automation and expertise. Marking lasers perform high-contrast, high-speed processing on all types of metal, even if they have undergone post-production processing or undergone invasive work (see Sandblasting for cast components). The type of marking we are talking about is also called DPM (direct part marking) because it is done directly on the component without labels or plates.

Lasers for Metal Marking

The most suitable laser technology for laser marking of metals is the fiber laser. It is ideal for laser marking, micromachining and cutting of all metals and alloys. It is also suitable for painted metals and metals with surface treatments such as anodised aluminium. The fiber laser can be used in its standard version as well as in its MOPA and Picosecond versions, which allow certain more specific results to be obtained on different types of metal. Moreover, compared to other stamping and writing technologies, laser marking is the most prevalent in the industrial world.

The MOPA laser can make coloured marks on steel and black marks on anodised aluminium. The ability to control its parameters with greater agility makes it a more versatile laser and ideal for those seeking aesthetic markings of a certain type. Laser marking is subject to less corrosion (due to the limited heat input). The edges of the laser engraving show fewer burn marks.

The Picosecond laser is a laser that allows impalpable, non-changing marks on metal. This makes it the most suitable laser for medical work. The smaller spot concentrates the energy in one spot, resulting in higher quality. It is also the first choice when it comes to applications that undergo post-marking treatments, such as citric or nitric passivation cycles.

Discover our fiber lasers

Marking processes on metal

Annealing

Surface laser marking

Pre-blast laser engraving

Sandblasting and shot peening are very frequent processes on cast components, necessary in the machining cycle but they also very invasive. One of the risks of these processes relates to traceability, i.e., the compromise (and therefore readability) of the DataMatrix code. At LASIT, we have developed a strategy to prevent the DataMatrix code from becoming unreadable after the various processes.

White laser marking

Paint removal

Engraving

Metals on which laser marking is performed

- Stainless steel

- Aluminium

- Anodised aluminium

- Hardened metals

- Alloy steels

- Super high-speed steels

- Titanium, titanium alloys

- Carbides

- Brass

- Copper

- Silver

- Gold

- Coated metals

Laser marking on stainless steel

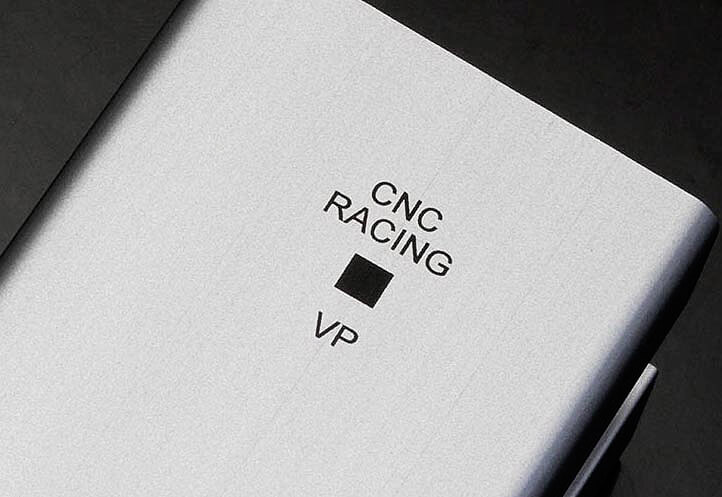

Marking 2D Codes on Metals

In the industrial world, laser marking is mainly used for traceability. As a result, laser markers are intended for a production line where a DMC or serial number takes center stage.

For both integration lasers and industrial automations, LASIT has gained great experience in the marking and verification of 2D codes on all types of metal, in particular for Automotive, Hydraulics (nameplates), Household Appliances and Taps, Smelters, Medical components.

Marking or engraving? What is the difference?

All laser marking or engraving methods have one thing in common: the laser beam is pulsed and releases energy at specific intervals. What changes are the speed and spacing, which determine the distance between one pulse and another.

In marking, the laser melts the material through heat and changes its shape to imprint a permanent code or mark. Laser engraving, on the other hand, vaporises the material. To do this, the laser must be powerful enough to vaporise the material in a few milliseconds and the material to be marked must have a suitable sublimation temperature. The laser beam penetrates deeper into the surface and removes the upper layers by sublimating them, i.e. through a direct transition from the solid to the gaseous state. This difference is not obvious to many, but for laser marking experts it is important.