Do you want to know the LASIT solutions for your sector?

Request a free consultation. One of our experts is ready to answer your questions and help you find the best solution for your needs.

By submitting this form you accept our privacy policy

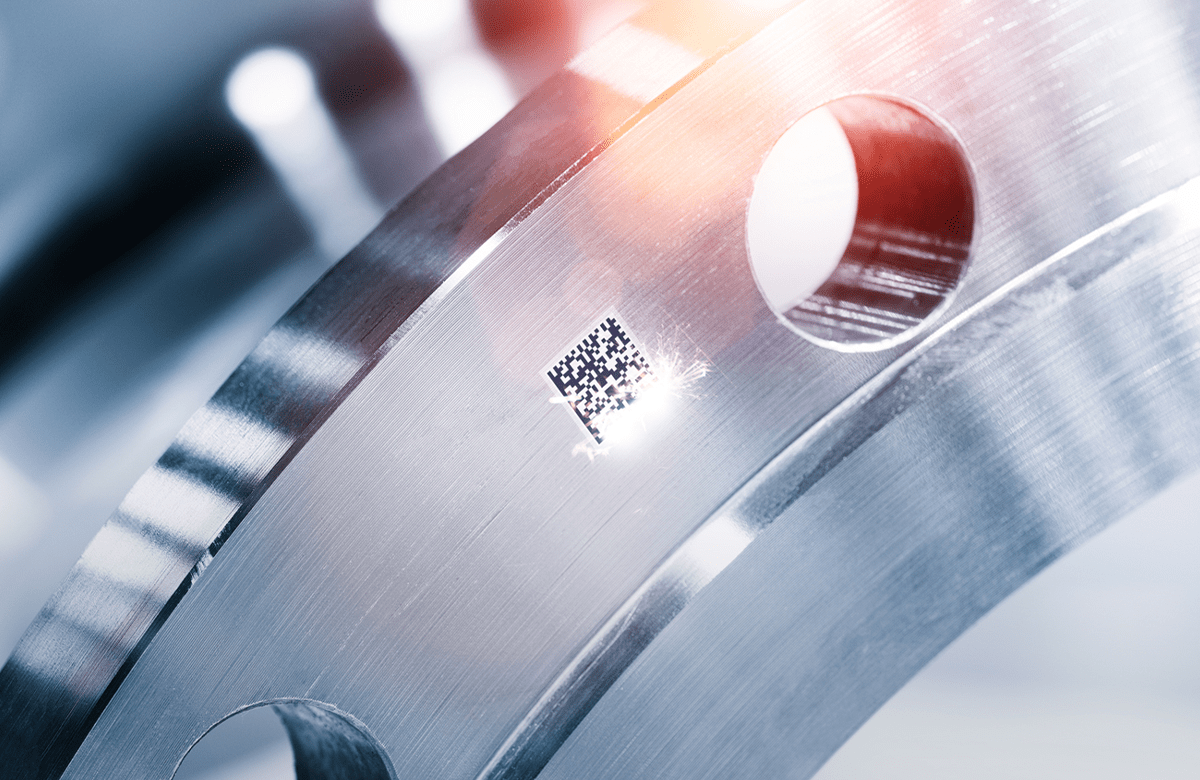

LASIT is the largest Italian manufacturer of laser markers. Our solutions are constantly becoming more advanced. We work on perfecting techniques and laser marking parameters every day, guaranteeing our customers speed, precision, and durability.

Today, we are answering the most common questions we get about laser marking and the systems that manage it.

If you have a question that we haven’t answered, please don’t hesitate to get in touch with us by chat or through our contact form here. Our experts are always available to help you find the best solution or to arrange a live demonstration at the company.

Different types of laser sources mark different materials. A traditional Fiber Laser (the most common source) can mark any kind of metal, while Traditional Fiber, MOPA Fiber, Green Laser, or UV Laser can mark plastic. CO2 Lasers work best on organic materials, like wood and glass.

LASIT has a laboratory with 20 lasers with different sources, powers, and accessories (like 3-axis-head for 3D marking). We perform free testing on your products, and we will identify the ideal parameters based on your needs.

Click here to make an appointment for a free consultation and to send us your products for testing.

The machine type depends on several factors, like the component you are marking (size and shape) and the required output. The main categories and most common markers are:

LASIT has also developed custom markers for special applications and requests, like the Flyroller for marking brake disks, the Penfeeder for pens, and the TowerLabel line for marking nameplates/plaques.

The price of a laser marker is determined mainly by two factors: the source and the type of marker. For example, in the previous question, we listed a series of models with very different structures and sizes, which affects the price.

The third factor to consider is the accessories. Laser markers can be integrated with different accessories for specific requirements.

This article explains in detail the cost of a laser marker and what you should consider before buying one.

Do you want to know the LASIT solutions for your sector?

Request a free consultation. One of our experts is ready to answer your questions and help you find the best solution for your needs.

By submitting this form you accept our privacy policy

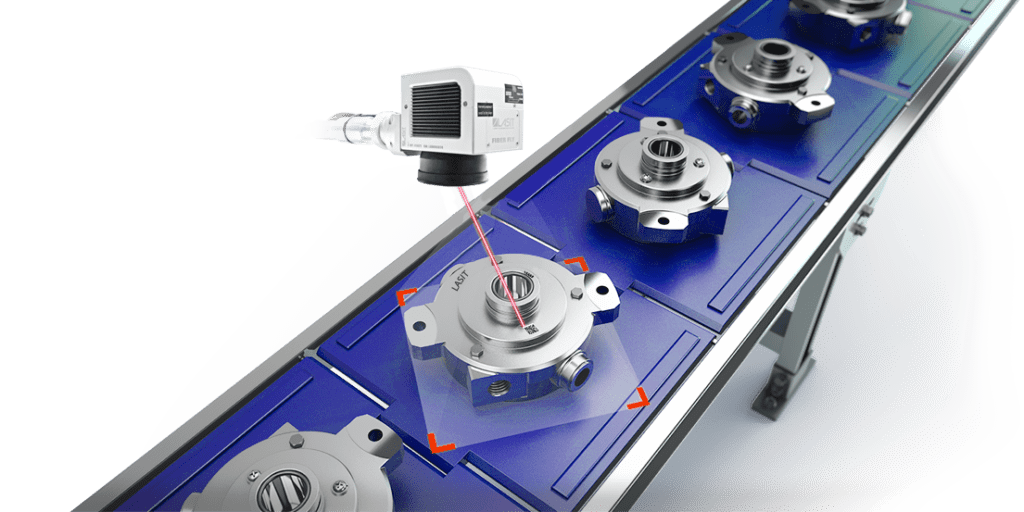

Laser integration into an existing line is very common. LASIT lasers can easily be integrated into automatic lines. Laser command management can be performed either with a computer or independently (without a computer). A computer can potentially manage an infinite number of lasers because LASIT lasers use PROFINET, PROFIbus, and PROFIsafe communication protocols.

LASIT’s integrated laser markers comply with all regulations for guaranteeing operator and line safety.

Download the brochure for our Powermark laser here to learn more about LASIT integrated lasers.

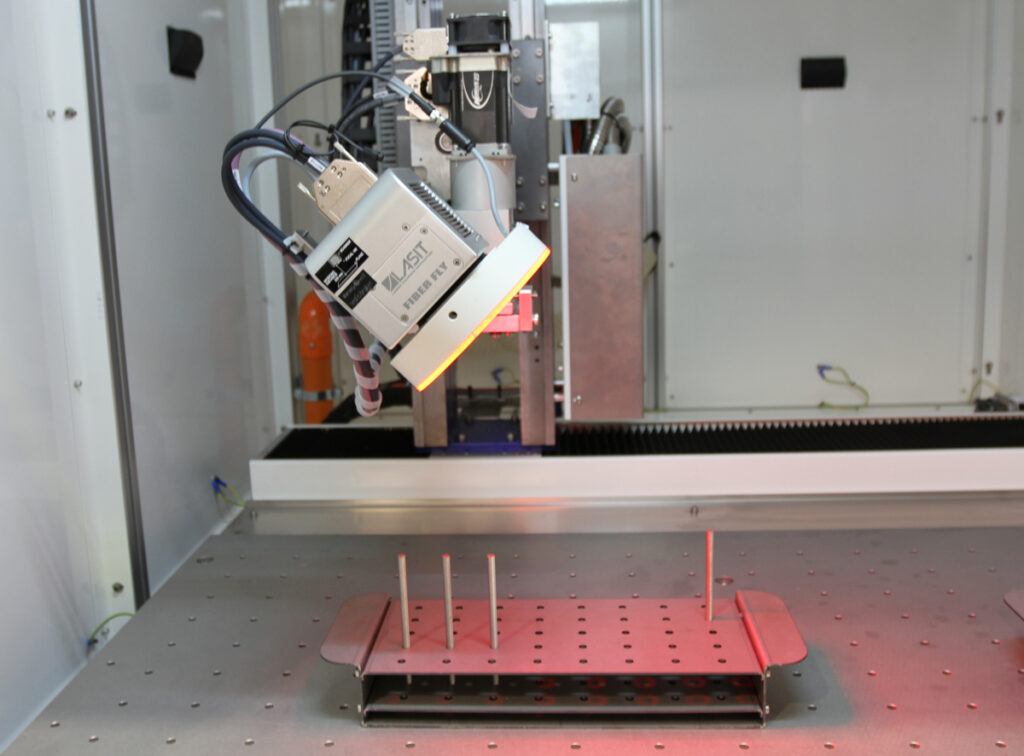

The answer to this question depends largely on the type of system you choose. You can mark multiple components in the same cycle, for example, inserting a pallet of parts in the machine. To do this, you need a larger focal lens (a lens that frames a wider area) for a machine with only a Z axis. On the other hand, if the laser head also moves on an X axis (horizontally) and a Y axis (depth), the general work area will be larger because the laser can physically reach more positions, and there will be no problems reaching all the parts on the pallet.

The laser is managed by software, which lets you set up all commands. LASIT FlyCAD software is user-friendly and intuitive. You can use the same laser to mark any code, graphics or logo. You can connect to factory MES ERP systems to manage the sequence of production orders or define a different layout to mark based on the QR code the video camera reads before starting the cycle.

With the 3-axis-head technology, you can manage the focal distance to guarantee the maximum contrast in marking even on components that are not flat. This is extremely important to speed up the process and increase laser engraving quality on irregular components, like die-cast, pens, bottles, home appliance parts, and many more.

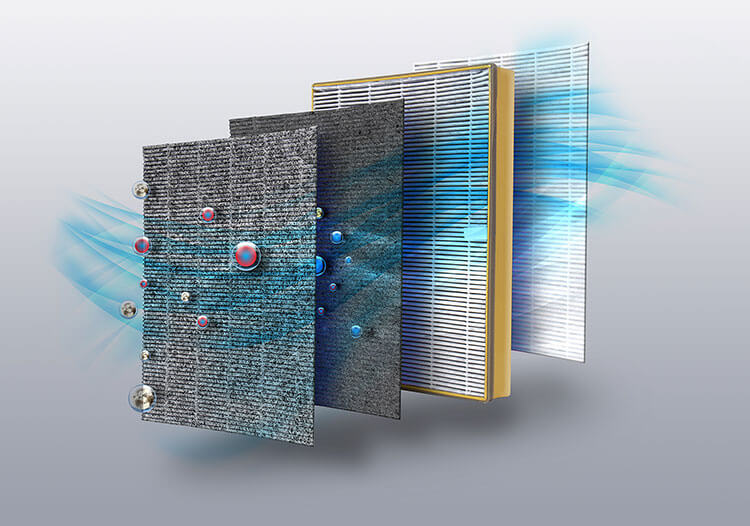

A fiber laser has an average operating lifetime of 100,000 hours at full speed. Maintenance depends on how well you take care of the machinery and the number of parts it has. The most frequent maintenance required is on the exhaust system, which has filters that need to be replaced when spent, and the focal lens, which can get dirty with the fine dust created during the laser engraving process.

An exhaust fan is needed when marking produces a lot of fine dust. Without a good exhaust system, the laser optical system, with the microdust particles that accumulate on the lenses, and the operator, who can inhale the fumes, suffer the worst consequences.

In this article, we explain when and why it is crucial to have an exhaust fan in your laser marker. All LASIT laser markers are set up to integrate an exhaust system, whether the customer’s plant has a central system or not.

Marking times vary based on the dimensions of what you want to mark and the engraving depth. Under identical conditions, the marking speed is determined by the power (Watts).

LASIT offers a full range of lasers and a laboratory with twenty sources that can be used to perform free tests on different materials and parts to optimize performance and identify the ideal laser parameters for each application.

Here are a few marking examples, where the engravings were made using the same laser source with different powers. This shows how the power affects the speed of the laser marking process.

LASIT Sistemi e Tecnologie Elettrottiche S.p.A.

Via Solferino 4

80058 – Torre Annunziata (NA)

P.Iva 02747991210

C.F 01803670643

Copyright © 2024